Have you ever ever wondered how Those people sleek, intricate metallic patterns in your favorite devices are made? It’s not magic, but instead the marvel of modern know-how: laser chopping. This technological know-how has revolutionized just how we method precision and design. From industrial laser cutting to CNC laser slicing, the advancements in laser reducing equipment happen to be nothing at all in need of outstanding. For those who’re interested in how a laser cutter will work or what makes it so exact, you are in the best spot!

Let’s get started with the basic principles: a laser slicing device employs a superior-powered laser beam to chop by means of products like metal, plastic, and wood. Picture a very hot knife slicing through butter—that’s a simplified analogy of how a laser cutter operates. The beam is incredibly focused and might be managed with precision, making it perfect for specific and sophisticated styles.

Laser Cutting Systems Things To Know Before You Buy

Industrial laser chopping has transformed producing by giving unparalleled accuracy. Compared with common methods That may entail a lot of handbook adjustments, a laser cutter can deliver consistent effects every time. This precision is vital in industries where even the tiniest mistake may be high-priced. Think of it as a super-skilled artist who will carve out intricate designs without the need of at any time breaking a sweat.

Industrial laser chopping has transformed producing by giving unparalleled accuracy. Compared with common methods That may entail a lot of handbook adjustments, a laser cutter can deliver consistent effects every time. This precision is vital in industries where even the tiniest mistake may be high-priced. Think of it as a super-skilled artist who will carve out intricate designs without the need of at any time breaking a sweat.CNC laser chopping, or Pc Numerical Regulate laser cutting, can take items up a notch by integrating Computer system technological know-how. Consequently patterns are made on a computer after which executed by the laser cutter with actual precision. It really is like having a digital blueprint that guides the laser to chop specifically wherever It is required. This method is very economical and makes certain that intricate designs is often reproduced effortlessly.

Laser cutting technology has come a long way in recent years. Today’s equipment tend to be more effective, speedier, and much more economical than previously prior to. They will tackle a broader number of materials and deliver larger-excellent cuts. It’s just like how smartphones have advanced—what the moment appeared futuristic is currently Element of our day to day life. Laser chopping technological innovation happens to be indispensable in different industries, from aerospace to automotive.

Laser Cutting Technology for Beginners

Precision laser cutting may be the cornerstone of contemporary production. The term “precision” refers to the ability to Reduce with a precise diploma of precision. This is particularly significant when dealing with higher-tolerance factors. Envision endeavoring to healthy a jigsaw puzzle piece into a certain place—precision laser slicing makes sure that every piece fits perfectly without any gaps.

Precision laser cutting may be the cornerstone of contemporary production. The term “precision” refers to the ability to Reduce with a precise diploma of precision. This is particularly significant when dealing with higher-tolerance factors. Envision endeavoring to healthy a jigsaw puzzle piece into a certain place—precision laser slicing makes sure that every piece fits perfectly without any gaps.With regards to laser reducing gear, there’s a lot to pick from. The sort of machine you'll need depends upon the material as well as complexity of the design. No matter if you’re seeking a higher-driven industrial product or a far more compact unit for modest-scale operations, there is a laser chopping method to choose from in your case. It’s a tad like deciding on the proper tool for the position; Each and every variety of kit has its distinctive strengths and applications.

Sheet steel laser cutters are specially noteworthy. These equipment are designed to take care of thin metal sheets with remarkable accuracy. They’re frequently Employed in industries that have to have exact steel elements, like inside the manufacture of electronic units or automotive elements. Envision slicing via a sheet of paper having a laser—now scale that up to metal, and also you’ve acquired the notion of sheet metal laser cutting.

Laser reducing providers can be obtained for people who might not require an entire-scale machine but still involve high-high quality cutting perform. These solutions allow for enterprises to outsource their chopping ought to experts who've the best equipment and know-how. It’s a easy selection for smaller sized assignments or for organizations that don’t have the means to take a position in their own laser cutting equipment.

Laser reducing techniques come with various characteristics that improve their performance. Fashionable systems often consist of Sophisticated controls, automatic loading and unloading, and actual-time checking. These functions help streamline the slicing method and be certain superior-excellent success. Visualize it given that the difference between an aged-fashioned typewriter and also a condition-of-the-art computer—know-how has created the procedure smoother and a lot more economical.

While in the realm of precision, laser cutting technological know-how stands out. The laser cutter’s capacity to generate cleanse, sharp edges with negligible waste is often a video game-changer. This is especially helpful in industries where by materials expenses are large, and every scrap counts. It’s like having a wonderfully tailor-made go well with—no excess fabric wasted, and anything matches just right.

But what about the environmental effect? One of the advantages of laser chopping is its reasonably low squander technology. As the laser is so specific, it cuts particularly where needed, lessening the level of leftover product. This efficiency not merely saves revenue but additionally can make laser chopping a far more eco-welcoming alternative when compared with some traditional approaches.

When picking a laser chopping device, it’s necessary to evaluate the certain requires of the jobs. Distinct equipment include several abilities, from cutting speed to content thickness. It’s like selecting a vehicle; you will need to view the article consider what capabilities are most vital in your driving desires. Equally, the best laser cutter will depend on your slicing requirements and creation objectives.

Another attention-grabbing facet is how laser slicing can handle elaborate geometries. Compared with other slicing methods Which may battle with intricate models, laser slicing excels at manufacturing detailed patterns and styles. Think about a sculptor who will carve even quite possibly the most delicate facts into a block of marble—that’s what a laser cutter can perform with products.

Laser Cutting Services Can Be Fun For Anyone

The flexibility of laser reducing can be worth mentioning. Whether or not you’re working with metals, plastics, or maybe fabrics, laser chopping know-how can adapt to diverse supplies. This adaptability can make it a well-liked decision across many industries, from fashion design and style to aerospace engineering. It’s like aquiring a multi-Resource which can tackle Practically any activity without difficulty.Concerning upkeep, laser chopping devices are rather simple. Common repairs is important to guarantee best general performance, even so the know-how itself is built to be long lasting and reliable. It’s much like looking after a large-finish kitchen equipment—routine upkeep helps preserve almost everything operating smoothly and proficiently.

Wanting forward, the way forward for laser reducing technological know-how seems vivid. Innovations proceed to arise, with developments in laser electricity, speed, and product compatibility. As know-how evolves, we can assume more thrilling progress in laser reducing. It’s a area that’s constantly to the leading edge—pun meant!

More About Cnc Laser Cutting

For the people keen on DIY jobs or modest-scale producing, laser cutting offers an accessible way to realize Experienced success. With the correct gear and a little bit of creativity, you can create custom find here types and prototypes that will be tough to realize with other methods. It’s like using a mini-factory right with your workshop.

In summary, laser reducing technologies has dramatically altered the landscape of manufacturing and style. From industrial laser chopping to CNC laser slicing, the advancements On this discipline have made precision, effectiveness, and flexibility available to an array of industries. No matter whether you’re seeking a laser slicing equipment for your business or exploring laser slicing solutions, comprehension the several components of this technologies may help you complete info make educated selections and take advantage of its Positive aspects.

Haley Joel Osment Then & Now!

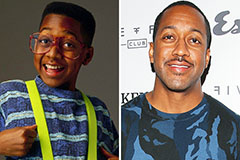

Haley Joel Osment Then & Now! Jaleel White Then & Now!

Jaleel White Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!